Ensuring that your restaurant's freezer is operating efficiently is paramount to the success of your business. A well-maintained freezer not only preserves the freshness of your ingredients but also conserves energy and saves money in the long run. Conducting weekly maintenance checks can prevent unexpected breakdowns and costly repairs. This guide will provide you with tips and best practices to carry out these checks effectively, including how to utilize modern tools like the tempCube Pro to streamline the process. By dedicating time each week to verify the functionality and cleanliness of your freezer, you can extend its lifespan and guarantee the quality of your products.

Importance of Weekly Maintenance Checks for Restaurant Freezers

Maintaining a restaurant involves numerous challenging tasks, among which ensuring the operational integrity of your freezer is paramount. This piece of equipment is crucial for preserving the quality and safety of food, and as such, requires regular maintenance. Conducting weekly maintenance checks on your restaurant’s freezer is not just about fulfilling a routine; it’s about safeguarding your business from unforeseen expenses and maintaining a consistent quality in your food offerings.

Ensuring Efficiency

Weekly maintenance checks are essential to ensure the efficiency of your freezer. Over time, dust and debris can accumulate on the condenser coils, leading to reduced heat exchange efficiency. This inefficiency forces the compressor to work harder, increasing energy consumption and costs. Furthermore, a well-maintained freezer maintains temperature more consistently, ensuring that food is stored under optimal conditions. This can significantly reduce the risk of food spoilage, thereby saving money on wasted ingredients and ensuring that the quality of food served to customers remains high.

Preventing Breakdowns

Another critical reason to perform weekly maintenance checks on your restaurant’s freezer is to prevent unexpected breakdowns. Diagnosing minor issues such as worn seals, frost buildup, or irregular noises can help you address problems before they escalate into major failures. A freezer breakdown can have a domino effect - from lost inventory and unhappy customers to potential health inspection violations. Regular checks allow you to schedule repairs during off-hours, minimizing disruption to your business operations. This proactive approach can extend the lifespan of your freezer and protect your restaurant from the financial strain and stress of emergency repairs.

Tools Required for Conducting Maintenance Checks

To carry out effective weekly maintenance checks on your restaurant freezer, certain tools are essential. Having the right tools on hand not only makes the process smoother but also more efficient, ensuring that you can accurately assess and address any potential issues.

Checklist

A comprehensive checklist is the foundation of a systematic maintenance routine. This checklist should include all the components that need to be inspected, cleaned, or replaced. Items on the list typically include checking the door seals for wear and tear, inspecting the condenser and evaporator coils for dirt and grime, ensuring that the interior and exterior of the freezer are clean, and verifying that the temperature and defrost settings are correctly adjusted. By following a detailed checklist, you can ensure that no component is overlooked and that your freezer is maintained in top condition.

Thermometer

A reliable thermometer is a must-have tool for conducting maintenance checks on your restaurant’s freezer. It is essential for verifying the accuracy of the freezer’s temperature control. Temperature inconsistencies can be a sign of an issue with the freezer's performance, potentially putting food safety at risk. An external thermometer can provide a second point of reference to ensure that the internal temperature display is accurate. This can help identify problems early on, such as failing components, that might not yet be apparent through visual or auditory inspection.

In conclusion, weekly maintenance checks of your restaurant’s freezer are vital for ensuring efficiency, preventing breakdowns, and maintaining the quality of your food offerings. Armed with a detailed checklist and a reliable thermometer, you can set a maintenance routine that safeguards your business against unexpected issues and ensures your freezer operates efficiently for years to come.

Step-by-Step Guide to Conducting a Weekly Maintenance Check

Conducting weekly maintenance checks on your restaurant's freezer is crucial to ensure it operates efficiently and to potentially avoid costly breakdowns. The key areas to focus on can be categorized into exterior inspection, interior inspection, and temperature checks.

Exterior Inspection

Begin with a thorough examination of the freezer's external condition. Look for any signs of physical damage, such as dents or scratches, which might not directly affect its performance but could indicate potential internal issues. Next, check the door seal or gasket for any tears, gaps, or signs of wear. A compromised seal can lead to air leakage, forcing the freezer to work harder and consume more energy. Also, ensure that the door hinges and handles are secure and in good working order to prevent air escape and maintain the unit's structural integrity.

Interior Inspection

Inside the freezer, start by checking for frost build-up or ice accumulation, which can indicate a failing defrost system or door seal issues. Excessive frost can obstruct air vents and reduce circulation, impairing the freezer's cooling efficiency. Next, inspect the evaporator coils and fans for dust and debris, which can restrict airflow and overwork the cooling system. Cleaning these components regularly can help maintain optimal performance. Additionally, ensure that the interior light is functioning correctly, as this is essential for safety and operational efficiency.

Temperature Check

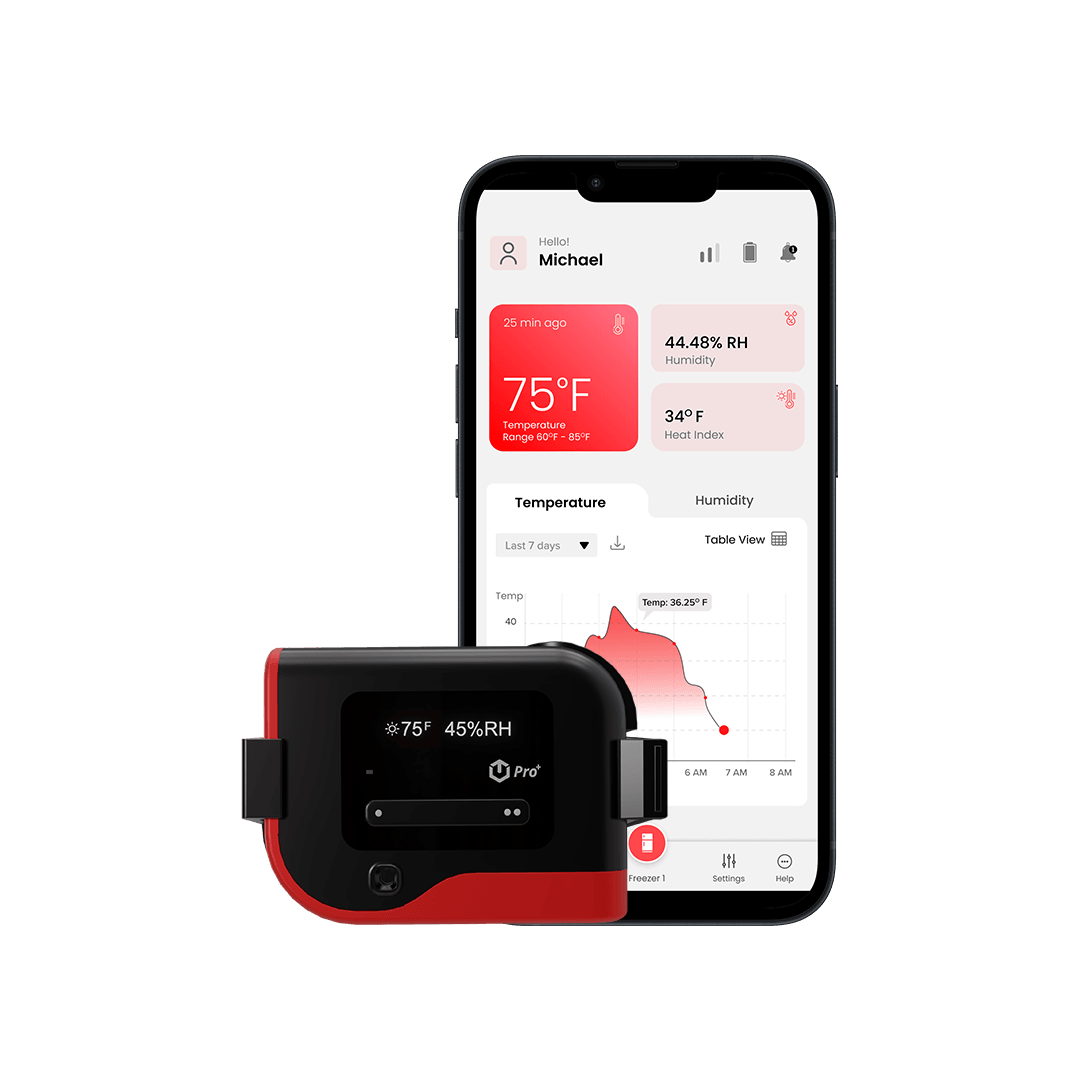

Using a reliable digital thermometer, such as the tempCube Pro, verify that the freezer's internal temperature is consistent with its set point. Ideally, the temperature should be at or below 0°F (-18°C) to safely store food items. Fluctuations in temperature can be a sign of malfunctioning components or an overfilled freezer. If inconsistencies are detected, investigate potential causes such as a failing compressor, inadequate ventilation, or a faulty thermostat and address them promptly to avoid spoilage and waste.

Best Practices for Maintaining a Restaurant Freezer

Adhering to best practices for freezer maintenance not only extends the lifespan of your unit but also ensures it operates at peak efficiency, which is critical for food safety and cost management.

Regular Defrosting

Regardless of whether your freezer has a manual or automatic defrost function, it's important to keep an eye on frost buildup. For manual defrost freezers, schedule regular defrosting sessions to prevent ice from thickening, which can impact the appliance's cooling ability and lead to overconsumption of energy. Automatic defrost freezers should be checked to ensure the defrost cycle is functioning correctly, as malfunctions can lead to similar issues as with manual defrost models.

Organizing Contents

An often-overlooked aspect of freezer maintenance is the organization of its contents. Properly organizing the freezer not only makes it easier to access items, reducing the door's open time and helping maintain the internal temperature, but also ensures efficient air flow. Avoid overpacking the freezer; air needs to circulate around items to keep them frozen. Use labeled bins and shelves to categorize food items, and regularly rotate stock to use older items first, minimizing the risk of freezer burn and waste.

By following these steps and best practices, restaurant owners and managers can ensure their freezers operate efficiently, maintain food safety standards, and prevent unexpected breakdowns. Regular maintenance checks are an investment in your appliance’s longevity and your business’s success.

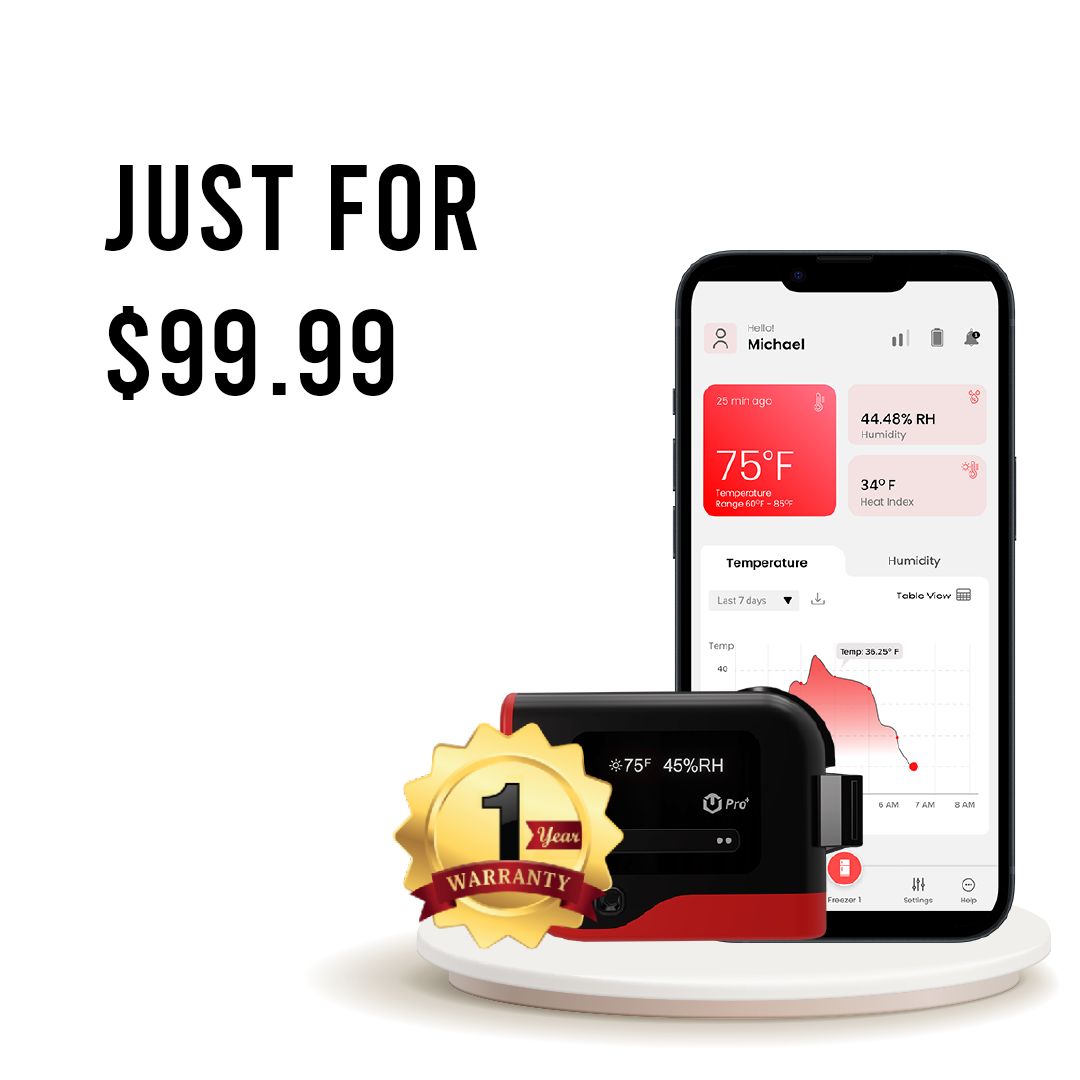

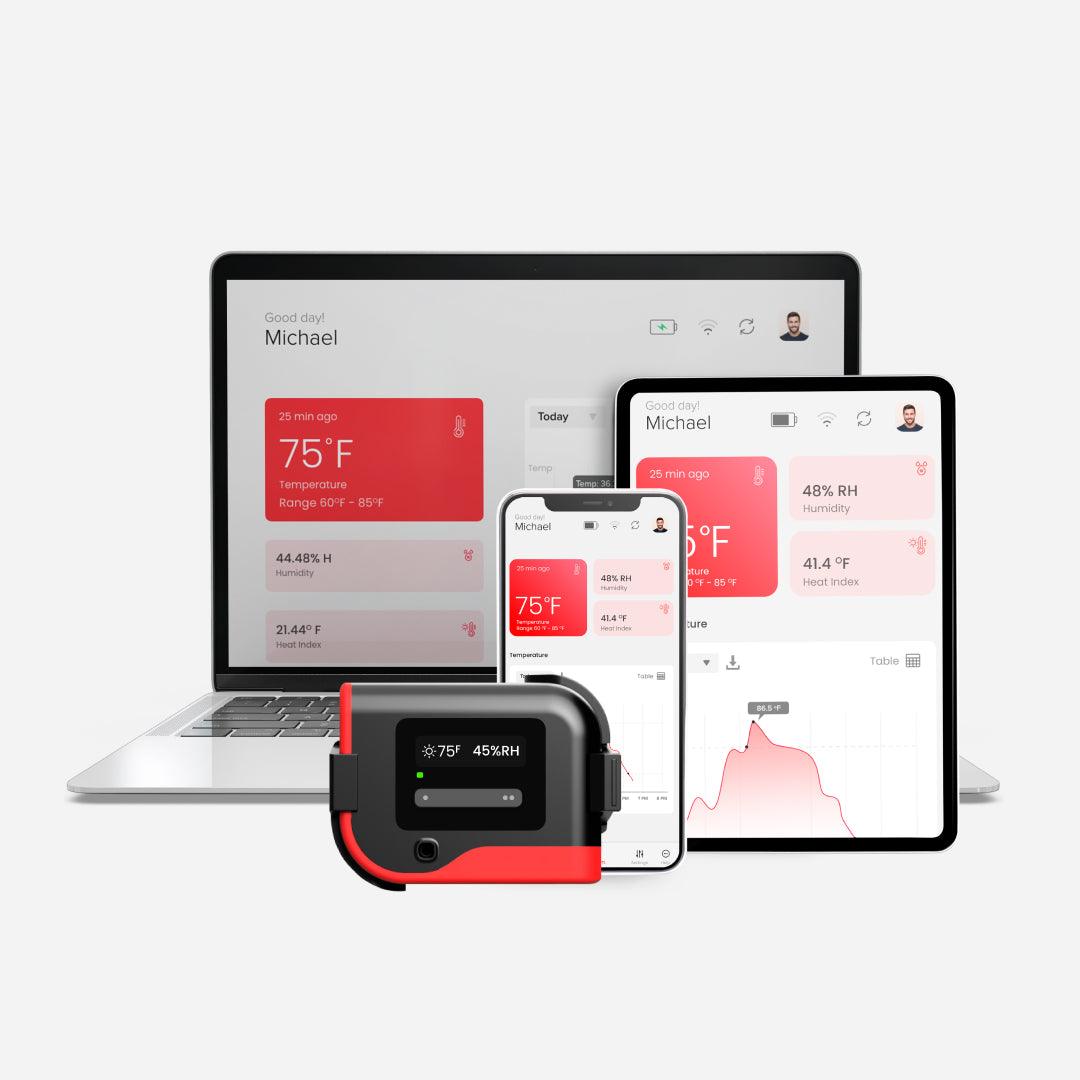

Utilizing tempCube Pro for Efficient Maintenance Checks

Conducting weekly maintenance checks on your restaurant's freezer is vital to its efficiency and to avoid costly breakdowns. With advancements in technology, tools like tempCube Pro have become indispensable in streamlining the process. TempCube Pro, a state-of-the-art monitoring system, can greatly assist in maintaining the optimal performance of your freezer units.

Real-Time Temperature Monitoring

One of the most critical aspects of freezer maintenance is ensuring the temperature remains consistent and within safe limits. TempCube Pro offers real-time temperature monitoring, which allows you to remotely keep tabs on your freezer's internal conditions without having to physically check the unit. This feature alerts you immediately if the temperature deviates from the set range, enabling you to act swiftly to rectify any potential issues.

Historical Data Analysis

Accurate record-keeping and analysis of historical temperature data play a key role in preventative maintenance. With tempCube Pro, you have access to a comprehensive record of temperature fluctuations over time. This data is invaluable for identifying patterns or recurrent issues that may suggest a looming problem, allowing you to proactively address it before it escalates into a major repair or causes spoilage of inventory.

Simplifying Routine Inspections

In addition to temperature monitoring, conducting physical inspections is an integral part of a comprehensive maintenance strategy. TempCube Pro can be integrated into your weekly checks by setting reminders for physical inspections, ensuring that tasks such as checking for ice buildup, cleaning condenser coils, and verifying door seals are not overlooked. This integration of technology with traditional maintenance practices ensures your freezer's longevity and reliability.

By incorporating tempCube Pro into your weekly maintenance checks, not only can you enhance the efficiency and reliability of your restaurant's freezer, but you can also save time and reduce the risk of unexpected failures. Taking full advantage of this technology will elevate your maintenance practices, ensuring your kitchen operates smoothly and without interruption.

Final Thoughts

Conducting weekly maintenance checks on your restaurant's freezer is not just a recommended practice—it's essential for ensuring the longevity and efficiency of your equipment. Regular monitoring helps you catch potential issues early, saving you from costly repairs or even more expensive replacements down the line. By following the outlined steps, including cleaning, inspecting, and using advanced tools like the tempCube Pro for real-time monitoring, you can maintain optimal operation conditions and keep your food storage safe and reliable. Remember, a well-maintained freezer not only contributes to the quality of your stored food but also significantly impacts your business's bottom line through energy savings and reduced food waste. Make these checks a priority, and your freezer will remain a dependable asset in your restaurant's kitchen.